Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Celebrating 100 years of innovation and excellence doesn’t happen without great people with great attitudes! This month we focus on our Domestic Sales Account Manager, Mark Elliott for his many contributions to Rexarc over the past 17 years. Mark started...

View Details

Did you know ASME vessels play critical roles in rocket engine test stands? Their certification and safety requirements are crucial in the development and certification of rocket engines as they are tested on the ground before they are used in...

View Details

This month’s employee spotlight features our party planning and company “chef,” Zachary Diehl. Zack is an Engineering Technician and joined the Rexarc team in 2011. When Zack isn’t creating culinary delights for company celebrations, his primary role is technical support...

View Details

Could your acetylene operations benefit from an ammonia scrubber? What is Ammonia: Ammonia is a colorless gas composed of nitrogen and hydrogen that has a distinct pungent smell and is widely used in various applications. However, ammonia is hazardous and...

View Details

How it Began: During a customer visit to Power to Hydrogen an introduction was made to Mary Powell at Ph Matter. pH Matter, LLC is a small business headquartered in Columbus, Ohio that specializes in developing materials for advanced energy storage...

View Details

In 1924, the United States witnessed many significant events. Our national athletes competed in their first winter Olympics held in Chamonix France. J. Edgar Hoover was appointed head of the Bureau of Investigation, that would later become the FBI. The...

View Details

HAPPY BIRTHDAY REXARC! 2024 is very special for those of us at Rexarc. With this new year comes a very important anniversary. Serving customers and industry since 1924, Rexarc is celebrating 100 years of innovation and excellence! History Through four...

View Details

Understanding and selecting coating options for wastewater treatment vessels is essential to extending the lifespan of tanks, pipes, and other equipment while also ensuring their structural integrity. Specialized coating systems provide a necessary barrier that protects against the harsh chemicals...

View Details

This month’s employee spotlight features our fearless leader and visionary, Rob Moyer. As our CEO and fourth generation owner, Rob has worked at Rexarc since 2002 and has led the company since 2012. From the start of his career in...

View Details

Pressure vessels play a large role in many water treatment methods. Water treatment is used to remove contaminants from water used for drinking, washing, and cooking, among others, so it’s a critical industry that everyone uses at some point. This...

View Details

Pressure vessels are designed with multiple key safety features so they can be used safely for whatever requirements they are rated for, as long as they are properly maintained. Without these safety features, pressure vessels can fail and cause serious...

View Details

Pharmaceutical manufacturing is a far-reaching, global industry that plays a role in your everyday life. Pressure vessels are used extensively in this industry to develop and transport medicines and the chemicals used to make them, but why are they such...

View Details

Maybe you’ve had an old pressure vessel sitting around for a while, either in use or in storage. How do you know if it’s safe to use for a new project or if you should invest in a new one?...

View Details

Pressure vessels play a major role in the development and deployment of renewable energy systems. Investing in renewable energy is an important part of developing a robust network of energy suppliers that are more sustainable long-term. In this article, we’ll...

View Details

Dynamic loads are one of the more complex types of applied forces to account for. It’s important to understand what they are and when you’re likely to run into them, since they can have a big impact on how your...

View Details

When engineers design pressure vessels, they take into account many types of forces acting on the vessel, such as static loads, in order to ensure the vessel can withstand those forces. Understanding what forces are applied and how the system...

View Details

Pressure vessels are used extensively in the food and beverage industry. It’s one of the largest industries using them, and no matter where you are, you’ve likely eaten or drank something that required a pressure vessel during its manufacturing, storage,...

View Details

Nondestructive testing (NDT), also known as nondestructive inspection (NDI), is a critical step of pressure vessel development. When a vessel is built, it has to be tested to make sure it was built properly and can be operated safely without...

View Details

Personal protective equipment (PPE) is gear that exists to keep people safe on the job. There are some regulations set out by the Occupational Safety and Health Administration (OSHA) to ensure workplaces are doing what they can to protect their...

View Details

One major user of pressure vessels is the chemical industry. They use many different sizes and types of pressure vessels to process, store, and transport chemicals for use in everyday life – everything from bottled soda to the cooling system...

View Details

Any gas distribution system needs to have the right pipe diameter to work efficiently and ensure the right amount of gas is available where it needs to be. This guide will help you figure out what pipe diameter will be...

View Details

Determining the material choices is one of the most critical steps of designing a pressure vessel. If you’ve decided that stainless steel is the right material for you, you will also need to know what grade of stainless steel you...

View Details

There is a lot of jargon when it comes to pressure vessels, and k-bottles are a good example. You might have seen k-bottles annotated in a schematic or diagram, or listed in an email from a colleague, but do you...

View Details

ASME standards are used by engineers, manufacturers, and other professionals across the globe to make sure designs and parts meet certain requirements. These requirements are important because they demonstrate a commitment to safety and quality in the created products. This...

View Details

If you have a pressure vessel or are in the process of purchasing one, you might be wondering how to get it ASME certified. ASME certification means the vessel meets industry standards for design and manufacturing, and will ensure you...

View Details

Congratulations to Kelly Pease for being awarded Safety Leader of the Year for 2023 by the Preble County Chamber of Commerce! Kelly received this award for her outstanding efforts to improve the health and safety of Rexarc employees.

View Details

Have you ever wondered how stainless steel is rolled into a cylinder to form a pressure vessel? It’s a manufacturing process that requires specialized equipment and trained experts to perform. See it in action below: [embed]https://www.youtube.com/watch?v=slHATiDc7-8[/embed] Why roll stainless steel...

View Details

Figuring out the budget for a project can be a complicated process even if it’s a simple one, and adding custom work can make it more complex. It’s important to have a good idea of how much a project will...

View Details

Many people think stainless steel can’t be affected by rust, but this isn’t true. No strategy to prevent corrosion is perfect. This article will help you understand how rust can impact your projects using stainless steel, and when you might...

View Details

On June 18th, 2023 a submersible vessel named Titan imploded on its way to visit the site of the Titanic shipwreck, instantly killing all five people on board. In the days since the accident, experts have started scrutinizing the design...

View Details

Stainless steel is often an economical, easily-machined option for a pressure vessel material, but there’s a lot to consider when choosing your materials. Is stainless steel the best option for your project? What other options are out there? What materials...

View Details

Choosing the right material for your pressure vessel is one of the most critical design choices to make. Stainless steel is one of the most popular choices, but do you know why it’s a great material to build a pressure...

View Details

Deionized water tanks are used to store water that has had most of a particular type of contaminant removed. To keep the water from regaining this contaminant, special measures must be taken. This article will go over what deionized water...

View Details

High purity acetylene has a wide range of uses, including flame spectroscopy, production of some plastics and chemicals, as a light source in places without access to electricity, and most commonly, as a fuel across industries. This article will help...

View Details

If you’re working with steel tanks and pressure vessels, you’ve probably heard of hydrogen embrittlement. It’s a type of corrosion that affects many metals when exposed to atomic hydrogen. This article will help you understand why it’s important, how it...

View Details

There are many subcategories of vessels used to hold liquids like DOT cylinders, tanks, and pressure vessels. They each have their own distinctions and uses. This article will help you figure out what type of vessel you need and what...

View Details

Pressure vessels are designed to maintain a difference in pressure between the vessel’s interior and the environment. They’re used across industries including aerospace, manufacturing, transportation, and more, but even though they’re common they have some particular design requirements that need...

View Details

Pressure vessels are used across dozens of industries in everything from researching new technologies to studying the stars. They’re highly specialized pieces of equipment with specific design requirements to ensure the safety of the people using them, so while there...

View Details

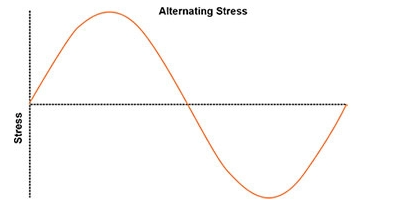

There are many types of loads and stresses that pressure vessels will encounter while they’re being used, including cyclic loading. So what is cyclic loading, and how does it impact the life of a pressure vessel? What type of load...

View Details

Preface Pressure vessels have stringent design requirements to ensure they will operate safely under the specialized loads and stresses they experience. This technical report contains a detailed analysis of metal fatigue caused by cyclic loading and early indicators of fatigue in high pressure stainless...

View Details

Have you ever wondered what propels rockets out of the atmosphere and into the stars? Maybe you’ve seen the trail they leave behind as they streak through the sky, burning up their fuel. This article will go over the most...

View Details

Corrosion is an inevitable part of maintaining a stainless steel pressure vessel, so how do you know when the amount of damage is too much to safely operate your vessel? What types of corrosion attack stainless steel? Stainless steel has...

View Details

Wondering how long your stainless steel will keep its corrosion resistance? It depends on the type of materials involved and how the object in question was designed. We’ll go over what stainless steel actually is, how it works, and if...

View Details

Cryogenic cooling combines heat transfer with low temperature physics to cool systems below about -250 degrees Fahrenheit (or -150 degrees Celsius, or 120 Kelvin), which is far colder than Antarctica, the coldest place on Earth. It’s a complex science, requiring...

View Details

Maybe you’ve got one lying around in the lab from a previous experiment, or you’ve found one being sold online at a cheaper price. But is it safe to reuse a stainless steel pressure vessel? It depends on several factors:...

View Details

3D printing has rapidly expanded its uses across the manufacturing industry over the last decade, but is it possible to use this technology to create a stainless steel pressure vessel? The short answer is yes. By using the right type...

View Details

Stainless steel pressure vessels have rounded ends as part of their design so they can safely contain their high pressure contents. Pressure applies a force over the entire surface area of the vessel. Rounding the ends prevents stress from building...

View Details

Sometimes the parts you need aren’t sold on the shelves. Rexarc ran into this problem trying to find the best fittings for our stainless steel pressure vessels, ones that would meet ASME standards for the very high pressures our vessels...

View Details

Rexarc’s commitment to working with customers on their projects has spearheaded the company’s ability to redefine industries since 1924. Our continuous evolution has taught us what strategies give our customers the support and information they need throughout the project lifecycle...

View Details

A stainless steel pressure vessel is a type of container designed to hold its contents at pressures above 15 psig (that’s 15 pounds of force applied per square inch, relative to atmospheric pressure). Pressure vessels withstand high pressures, applied externally...

View DetailsOutsourcing Feedwater Deaerator Shells Can Alleviate Workforce Pressures for Boiler Fabricators As an industrial boiler manufacturer, you want to remain focused on building the best boilers ever. The changing workforce, supply chain issues, and economic challenges are vying for...

View DetailsImplementing Manifolds in Small Gas Distribution Systems Beneficialn Safety, efficiency and resource effectiveness improve with implementing a manifold if you use just three cylinders per week If your gas supply does not have a manifolded central gas system, you may...

View DetailsThis content is password protected. To view it please enter your password below: Password:

View DetailsLooking Forward with Agility, Persistence and Innovation When you’re looking for an ASME-coded pressure vessel or custom fabrication partner, the company’s culture could make a huge difference in the service and product that you can expect. At Rexarc, a few...

View Details

Questions to Ask to make your project go smoothly Discussing Stainless Steel Tank Expectations Leads to Best Outcomes When engaging a potential fabricator, have a discussion with that manufacturer to help them understand how your tank will be used, the...

View Details

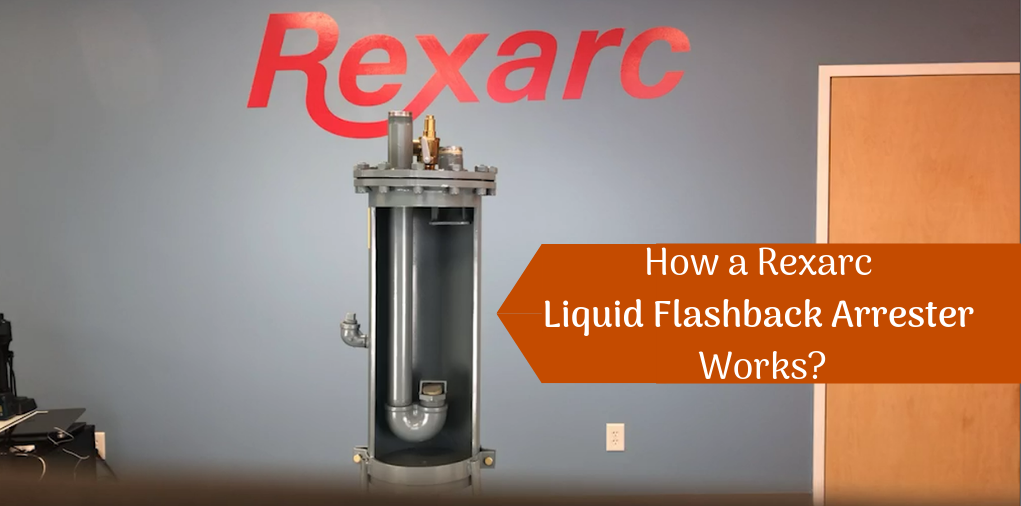

Annual Flashback Arrestor Maintenance Enhances Safety Safety is key to those working around gas distribution systems. A Rexarc Liquid Flashback Arrester (LFA) on a system ensures safety and the continued efficient and effective operation. Understanding how the LFA works and...

View Details

In early 2020, Hudson Space Systems was looking for a partner who could manufacture a pressure vessel that could endure extremely high pressures. So, they turned to the ASME membership directory. That’s where they found Rexarc International. Trust, but verify...

View Details

Steel Tanks, Pressure Vessels and Piping Can Be Available When You’re Ready To Build It is difficult to escape supply chain frustration right now. Volatile pricing, stretched delivery dates and even lack of input availability are making it nearly impossible...

View Details

Learning From Failure Part of Our Continuous Improvement Culture We’ve been in business for nearly a century, specializing in steel tank fabrication and adding product lines, like pressure vessels and boiler deaerator systems. We take great pride in building products...

View Details

Oxy-acetylene torches and fuel pipelines are used for welding, cutting, heating, and brazing in metal fabrication workshops and several other industrial facilities. The design of these torches has evolved over the years. Today, you will see oxy-acetylene torches in safety-centered...

View Details

As an industrial boiler system manufacturer, you know corrosion causes most system failures. After all, a boiler system is constantly exposed to the corrosive effects of water and gases. Not only is this a performance issue, but a safety one...

View Details

Your company builds beautiful industrial boilers. You and your team are great at manufacturing these amazingly complex systems. You also likely want your company to be better and to grow so that you can offer more opportunities to your team...

View Details

Rexarc, which started by designing and manufacturing Sight Feed Generators in 1920s, is today considered one of the leading fabricators of ASME and non-ASME pressure vessels, custom tanks, and acetylene generators. The company also offers pipe fabrication services. Always focused...

View Details

Rexarc is one of the industry-leading manufacturers of custom pressure vessels for commercial and industrial applications. Since 1924, innovation, customer service, and identifying and capitalizing on the growth opportunities have been at the core of the business at Rexarc. Following...

View Details

The pressure vessels designed and fabricated to ASME standards are widely used across industries. These pressure vessels stand out due to their fabrication excellence and safety. Today, you can find several manufacturers specializing in ASME pressure vessel fabrication in US....

View Details

Safe and efficient operation of your pressure vessel can be interrupted by poor materials and weld choices. Making good decisions from the earliest stages of specification and design will ensure the efficient performance expected. In the engineering phase, be sure...

View Details

Pressure vessels and boilers are widely used across industries for many purposes. Owing to their importance and diverse usage, pressure vessels are available in varied specifications, with temperature and pressure limitations, and in an array of materials. There are many...

View Details

Rexarc specializes in the design and manufacturing of ASME and non-ASME custom pressure vessels in the US. Their continuous investment in technology and improved manufacturing processes enables to assure quality and the fastest turnaround times in the industry. The company...

View Details

Acetylene, oxygen, and inert gases are industrial gases, which find applications across industries. Oxygen-acetylene combination produces localized heat, and is widely used for different types of heating applications. Be it acetylene, oxygen, or inert gases, each of these have typical...

View Details

Meet Your ASME Pressure Vessel Requirements With Rexarc Pressure vessels and boilers are designed to hold different types of fluids at various pressure levels across industries, and their failure could endanger human lives and damage property. Industrial process managers rely...

View Details

Compressed gas cylinders filled with fuel gases like acetylene as well as fuel propellants like oxygen are used in various industrial facilities. These gases are prone to flashbacks and backfire, which mainly occur due to human errors such as wrongly...

View Details

With the United States and other world governments imposing stricter bans on travel and other unnecessary activities and advocating social distancing to curb the outspread of COVID-19, manufacturers are facing supply chain challenges. However, many leading manufacturers like Rexarc have...

View Details

Regulators or changeover manifolds are an integral part of industrial gas distribution systems because their primary function is pressure regulation. They help convert the pressure of a gas received from a source to the working pressure required for use. In...

View Details

Pressure vessels are used in various industries such as chemical, military and defense, petrochemical, as well as energy, oil, and gas for storage of toxic and non-toxic gases, chemicals, and liquids, among others. The safety of these vessels is the...

View Details

Pressure vessels are cylindrical close containers used in various industries for storing various types of toxic and non-toxic elements such as gases, liquids, and semi-solids. These fluids are stored at different pressures and temperatures in bulk quantities. If the pressure...

View Details

Hoses are used across industries to transfer various types of fuel gases for welding and cutting. Fuel gases such as acetylene, propane, and butane utilize different types of welding hoses. These hoses may differ in terms of their lengths and...

View Details

Acetylene is today considered one of the most popular industrial gases, which is distributed through manufacturing plants in pipelines and manifolds. Along with acetylene, oxygen and other inert gases are also used in various industrial applications. These pipelines and manifolds...

View Details

Working with metals is not easy because they are reactive to heat. These metals are transformed into various shapes employing different techniques. Welding is one of these techniques, where metals are fused by the application of pressure and heat, as...

View Details

Acetylene gas cylinders find large applications in the metal fabrication industry among several others. Although these cylinders provide several advantages, they may take up a lot of space, and require regular replacements, too. They also increase rental costs and demand...

View Details

Oxy-fuel torches along with fuel pipelines are used in various metalworking facilities for cutting or welding strong metals. The fuel gas is directed at the metal at a particular pressure. Any change in the pressure may cause the flame to...

View Details

Acetylene gas plants are used for various continuous process applications such as for ethylene production in the chemical industry, in the metal fabrication industry for oxy-acetylene welding, cutting, brazing, and so on. There are several acetylene gas plant manufacturers in...

View Details

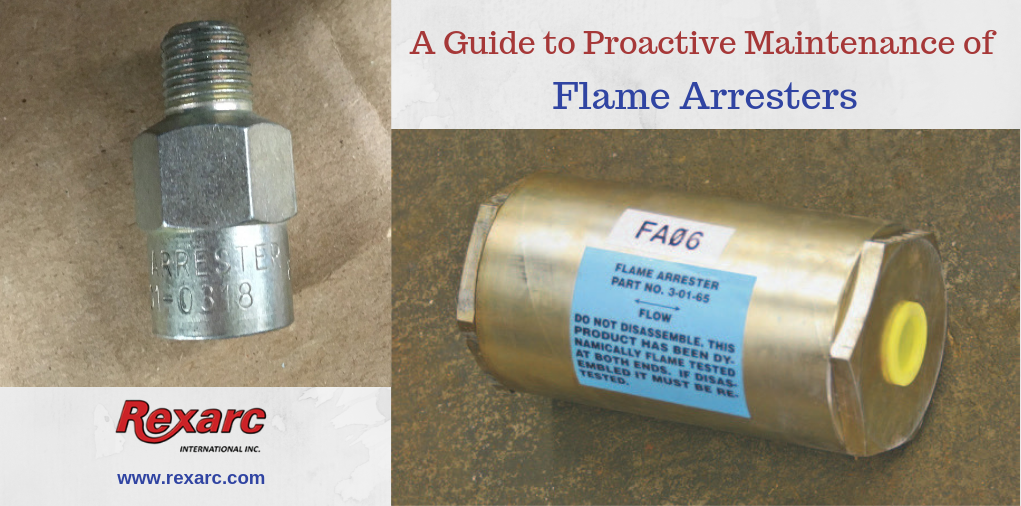

Flame arresters are used in acetylene pipelines to interrupt the combustion of flames, which may attain high speeds, and cause heavy damage unless they are stopped. These devices feature heat sinks having a high surface-to-volume ratio, as well as narrow...

View DetailsAcetylene has become one of the popular industrial gases owing to the several advantages it offers. However, the gas has many impurities, which makes it difficult to use in its original form. Thus, it is purified using a specially made...

View Details

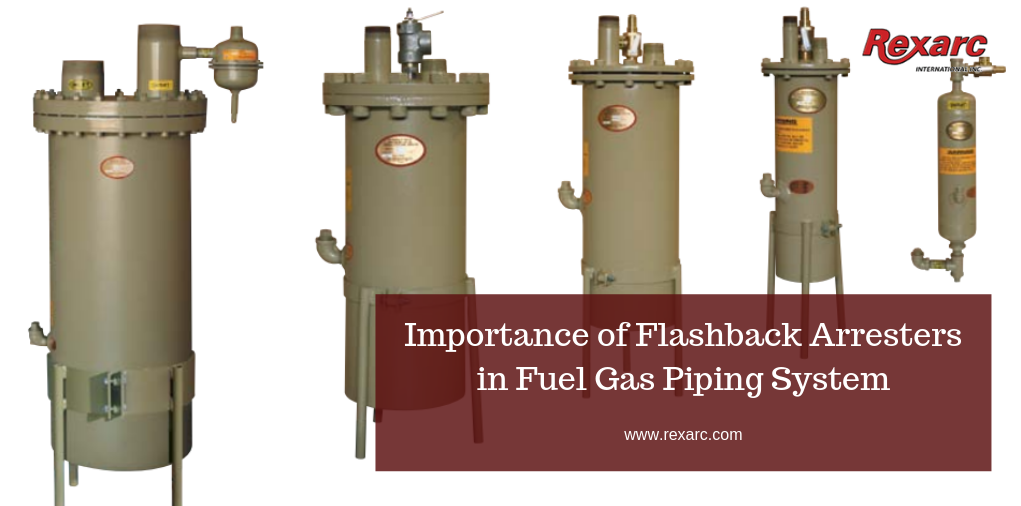

Today, many manufacturing processes demand flammable industrial gases. Thus, it has become important to use a variety of hazard prevention and safety tools when carrying out these processes. Of the various tools, flashback arresters have become one of the must-have...

View Details

Welding is one of the intricate manufacturing processes used in various industries. The process may vary largely according to the material that is being considered for welding, magnetic or non-magnetic, ferrous or non-ferrous material, and so on. Gases are one...

View Details

Today, various types of compressed gases such as acetylene, propane, oxygen, nitrogen, helium, argon, and so on, are used across various industries. Filled into cylinders, these compressed gases may pose chemical and mechanical hazards depending on their properties. They are...

View Details

Acetylene is one of the most popular gases used across industries for oxy-acetylene welding and cutting. It is also used as a raw material for the production of various chemicals such as polyester plastics, polyurethane, and more. Acetylene gas is...

View Details

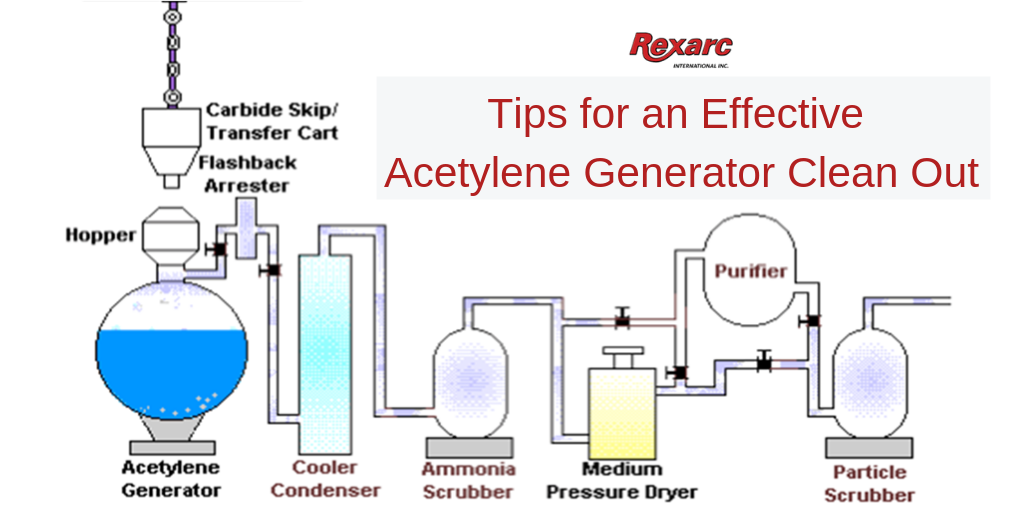

Acetylene, being one of the widely used compressed gases, is nowadays produced on a larger scale using acetylene plants. As with any regular compressed gas generation equipment, these plants are fitted with several parts that play a key role in...

View Details

Over the years, the use of several compressed gases in industries has increased. Acetylene is one such gas that has gained immense popularity in various industries because of the several benefits it offers. Today, acetylene production and filling plants are...

View Details

Acetylene is one of the common raw materials used in the production of other chemicals. It is also employed for welding various metals. Being a popular industrial gas, acetylene is often produced using acetylene generation plants. Rexarc is one of...

View Details

Acetylene is an industrial gas with several beneficial properties, which makes it easily popular over other industrial gases such as methane, propane, and so on. Though all these gases are hydrocarbons, the acetylene differs from them in terms of its...

View Details

Acetylene (C2H2) is a highly flammable gas; it is colorless and has a peculiar odor. Acetylene gas plants are units where acetylene gas production is carried out. At the plant, acetylene is produced either through a chemical reaction or cracking...

View Details

Welding is an important fabrication processes in various manufacturing industries. There are different types of welding procedures. One important type is gas-welding. In this type of welding, the heat necessary for the process is produced by the combustion of oxygen...

View Details

Acetylene is the hottest burning industrial fuel gas. It is also volatile at full cylinder pressure. To help stability, acetone gets added to the cylinder for safe transportation, storage and use. Acetone also stabilizes the acetylene in the cylinder and...

View Details

Pressure vessels serve different purposes, and they are used across various industries. These vessels may be compressed with different types of industrial gases. Some common gasses include air, acetylene, helium, oxygen, or nitrogen. Being a popular industrial gas, acetylene is...

View Details

Acetylene is one of the popular industrial gases used across the world. The gas offers several advantages which has contributed to its widespread use across various industries. Although human-friendly, the gas also possesses several hazardous properties, which may lead to...

View Details

Industrial gas cylinders have been around for a long time. They are widely used for welding, medical applications, fermenting liquids, and several other applications across various industries. In addition to these, new applications for these cylinders are emerging, as new...

View Details

Acetylene gas is a product gas, which is manufactured for use in different industries such as manufacturing, petrochemicals, biotechnology, environmental protection, etc. Like other industrial gases, this gas also has several impurities such as particulates, organic and inorganic matter, water,...

View Details

Safety hoses are important in industries where liquids and gases get moved. Most times, these hoses are made from sturdy materials, which helps improve their performance in harsh conditions. Do you think the sturdiest construction is enough to ensure its...

View Details

We are a one stop shop from custom vessel production to full skidding, plumbing and instrumentation.

We stand by our processes and communicate with you on your project status as much or as little as you would like.

We continually reinvest in our people, business, and equipment technology to ship quality products on time.