Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Unlike most industrial gases, Acetylene is a type of gas that is dissolved into a solvent to keep it safer and more stable. Due to its chemical composition it is an extremely useful gas for the chemical industry but for commercial cylinder applications, is mainly used in cutting and welding processes. It has a burning temperature up to 5,700℉ (3,148℃), when burnt with oxygen. Also, pure samples of the gas can decompose violently. Due to all these reasons, critical understanding and steps need to be taken when handling and storing acetylene gas cylinders. This post provides information you need to know on the topic.

A Brief about Acetylene Cylinders

While many people may logically conclude that acetylene is stored in standard high pressure cylinders which are hollow in construction and gas storage use, this point is not true. Acetylene cylinders are a separate, dedicated and special type of cylinder that is used to store and transport the gas above pressures of 5 psi (.3 bar). A standard acetylene cylinder has a length of 30” (76.2 cm) and has a 10” (24.4 cm) diameter. The cylinder’s construction comprises the following materials and components:

1. The exterior of the cylinder is all steel in construction.

2. The interior of the cylinder body is constructed of either a fire resistant or monolithic filler material known as the ‘porous mass’.

3. The porous material is saturated with acetone or dimethyl formamide (DMF).

4. Older cylinders have fuse plugs in the bottom of the cylinder.

5. The top of the cylinder comprises brass valves, a metal cap, and often safety fuse plugs.

Knowing the composition and traits of an acetylene cylinder will help a user understand and safely handle and store acetylene cylinders.

Instructions for Storing Acetylene Cylinders

There are specific instructions that users need to follow when storing acetylene cylinders. These instructions are divided into three parts.

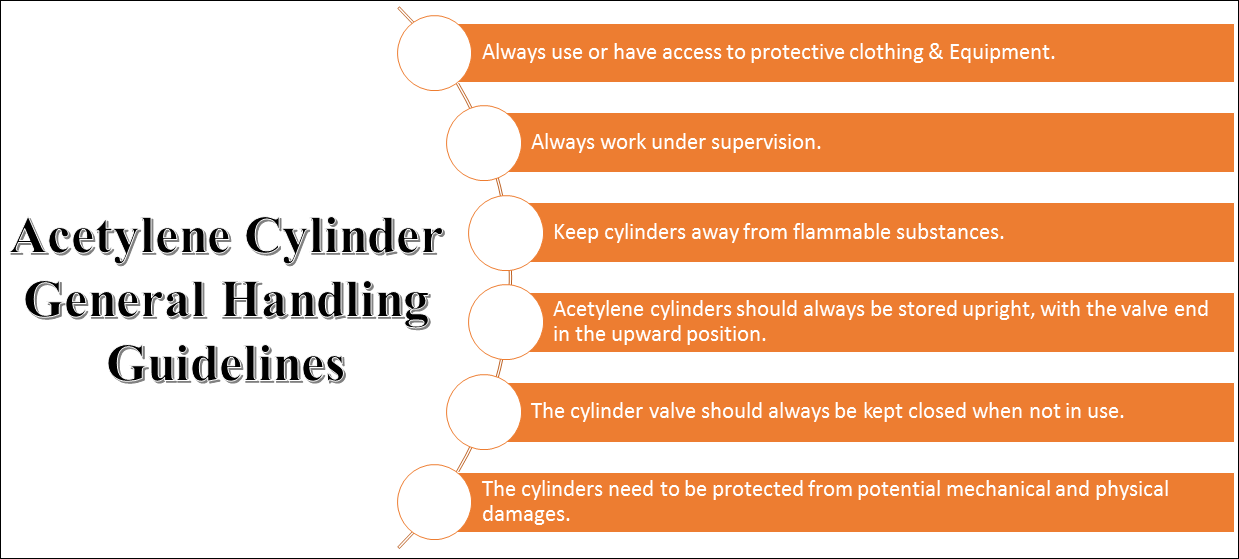

1. General Storage Guidelines:

a. Always use and/or have access to protective clothing and equipment when handling the cylinders. These include gloves, goggles, cotton clothing, and fire extinguishers.

b. Always work with, or under the supervision of qualified personnel.

c. Keep cylinders away from any kind of flammable substance.

d. Acetylene cylinders should always be stored upright, with the valve end in the upward position.

e. The cylinder valve should always be kept closed when not in use and the fuse plug(s) should be checked to verify a tight seal.

f. The cylinders should never be stored in extreme temperature environments. In warm environments, the temperature should never exceed 125℉ (52℃). In freezing temperatures, the pressure may drop within the cylinder to nearly zero and when flowed, acetone may leak from the cylinder resulting in clogging of downstream equipment such as a regulator.

g. Empty and filled acetylene cylinders should be stored separately as well.

h. Acetylene cylinders should be stored separately from cylinders containing other gases.

i. The cylinders need to be protected from potential mechanical and physical damages.

2. Indoor Storage:

Cylinders that are stored indoors need to be placed in an area with the following guidelines:

a. The storage area should have a fire resistance rating of 2h. (This is the rating for flammable gases.)

b. The area should have the requisite amount of ventilation, however, it should also prevent gas migration within the building.

c. Acetylene storage areas should meet Class 1, Division 1, Group A ratings with all equipment in the area meeting this classification.

d. The cylinders should be stored in an area that is at least 1 meter away from elevators, ramps, fire exits, stairways, passages, and corridors.

3. Outdoor Storage:

Cylinders that are stored outside need to be placed in an area with the following guidelines:

a. Fencing at least 71” (1.8 meters) high to prevent unauthorized entry.

b. Lockable (and locked) gates when the area is not in use.

c. The enclosed area should be various distances from any building depending on the amount of acetylene stored:

These various points will help users of acetylene cylinders to ensure proper cylinder handling and storage, while reducing the chances of explosions. If you are not clear and/or require more information, it is always best to consult a qualified technician prior to handling and storing your acetylene cylinders.

We are a one stop shop from custom vessel production to full skidding, plumbing and instrumentation.

We stand by our processes and communicate with you on your project status as much or as little as you would like.

We continually reinvest in our people, business, and equipment technology to ship quality products on time.