Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Today, many manufacturing processes demand flammable industrial gases. Thus, it has become important to use a variety of hazard prevention and safety tools when carrying out these processes. Of the various tools, flashback arresters have become one of the must-have tools in manufacturing facilities, where oxy-fuel welding and cutting is performed. Do you want to know how these devices help in preventing fire hazards in these facilities? The post discusses these devices and their working in detail.

What are Flashback Arresters?

In facilities where oxy-fuel gas operations are performed, gases are transferred through cylinders, hoses, or pipes during the process. During this transfer, the gas may leak, spark, or may be subjected to an irregular pressure. In all these situations, the fire moves in a reverse direction towards the fuel source. This phenomenon is known as a flashback. If unchecked, this flashback may enter regulators, hoses, or gas cylinders. Consequences of a flashback may range from slight damage to the equipment to a major explosion that may result in property damage and/or death.

A flashback arrester helps avoid an incident by quenching the fire before it gets to the cylinders. These devices are distinguished into two main types— wet and dry flashback arresters— depending on the type of arrester used. If the system uses a flame arrester — this style uses a dry barrier to quench this fire. Flame arresters can be fitted to the torch and the regulator and a flashback arrester typically protects the fuel gas source in facilities where fuel gases and oxygen are used together.

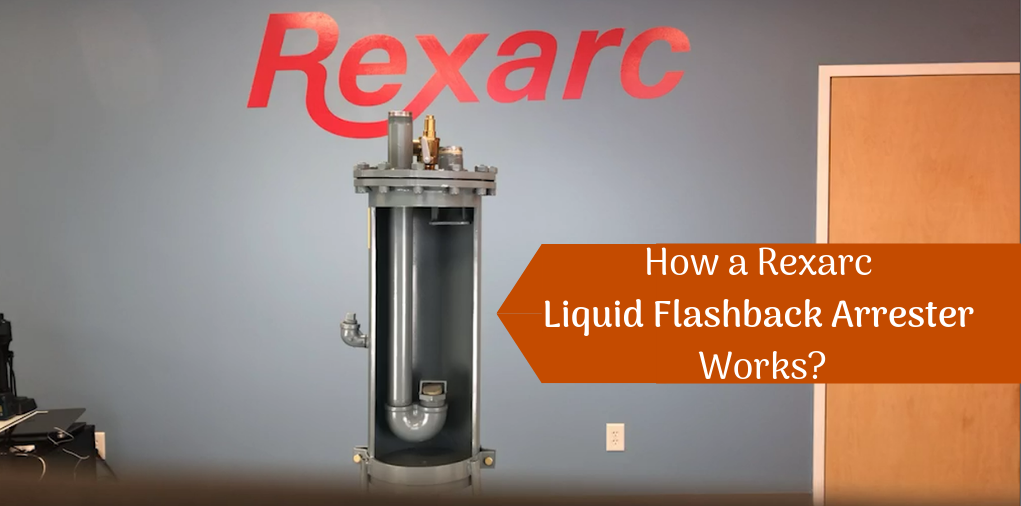

There are various flashback arresters available in the market. Rexarc’s liquid flashback arresters have maintained a long-standing popularity because of design safety and reliability. How do these liquid flashback arresters work? Read the next section to know more.

Working of Rexarc’s Liquid Flashback Arresters Explained

Liquid flashback arresters by Rexarc are designed for medium pressure operations. These devices help protect the main gas supply from flashback or reverse flow. Rexarc’s flashback arresters are designed for use in facilities, where acetylene gas is used for oxy-welding and cutting processes as well as where any fuel gas is combined with an oxidizer at point of use.

The flashback arresters feature the following major components:

Now, let’s see how each of these components aid in the functioning of the device.

To operate as designed, the levels of the flashback fluid must be maintained in the device as recommended by the manufacturer. This fluid must be changed annually to prevent contamination.

These liquid flashback arresters have been successfully used across various facilities over the past 60 years. For more information on these flashback arresters, please visit our Liquid Flashback Arrestor Devices page.

We are a one stop shop from custom vessel production to full skidding, plumbing and instrumentation.

We stand by our processes and communicate with you on your project status as much or as little as you would like.

We continually reinvest in our people, business, and equipment technology to ship quality products on time.