Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

Rexarc is currently open from 7:30 AM – 4:00 PM EST, Monday – Friday. Read More

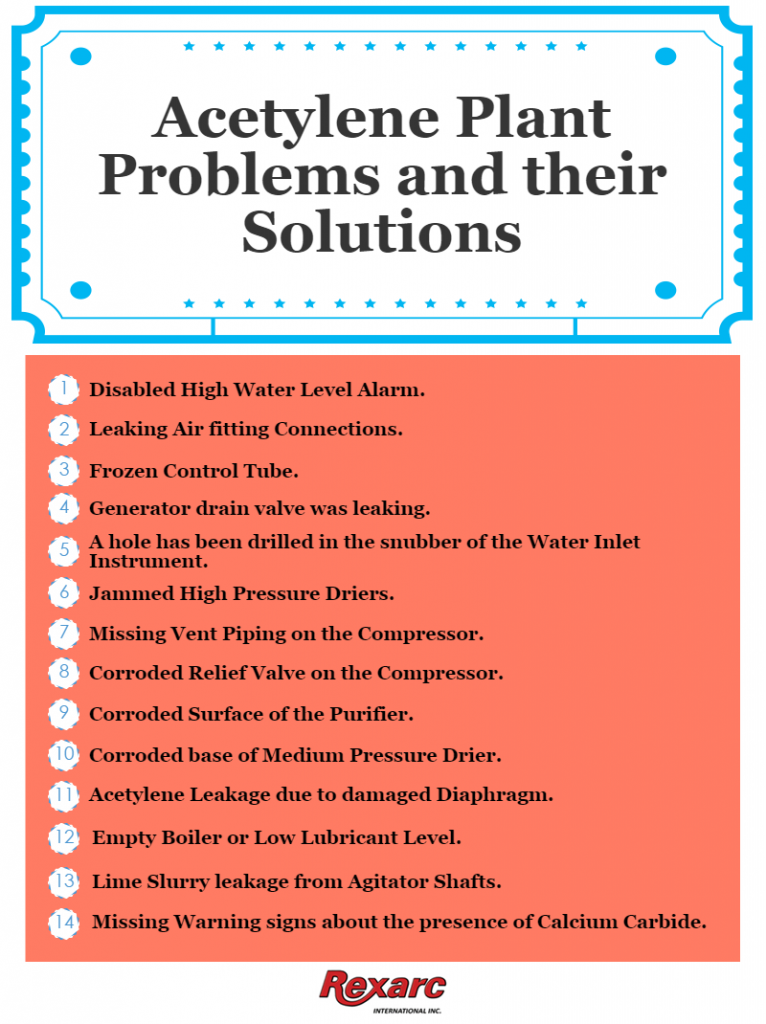

An acetylene plant audit should be conducted on a regular basis to verify the state of the components. A professional will be able to help streamline processes to increase the overall efficiency of your acetylene plant. This is extremely important if your plant is more than 3 years old. An acetylene plant audit should be conducted every 6 months to a year. Conducting an audit on your own on a daily or weekly basis is also helpful in checking the condition of your plant.

When conducting these audits internally, it is important to identify process owners and ensure that these audits are conducted only by people who are technically sound in the particular field. In-depth knowledge of the different components will ensure that they are able to identify any problems/ defects at the initial stage. Acetylene plant audit service providers will also be able to conduct training sessions to train your staff on proper handling of equipment as well as the right method of conducting audits at an organization level. However, you should supplement your efforts by getting a professional audit conducted every few months.

Maintenance in acetylene plants should be performed periodically to identify problems specific to your plant. A professional acetylene plant audit will help you not only identify these problem but also ensure that these problems don’t reappear. Simple maintenance procedures will keep your components working in a healthy condition. This in turn increases the efficiency of the plant driving up productivity and reducing time. In short, it helps reduce costs and increases profit.

In the previous posts, we discussed several problems associated with acetylene plants. The importance of audits cannot be overstated.

Please do feel free to get in touch with a Rexarc representative in case of any queries.

We are a one stop shop from custom vessel production to full skidding, plumbing and instrumentation.

We stand by our processes and communicate with you on your project status as much or as little as you would like.

We continually reinvest in our people, business, and equipment technology to ship quality products on time.